Comparisons

Comparisons between Deep Sea Massive Sulphides and Near Earth Asteroids

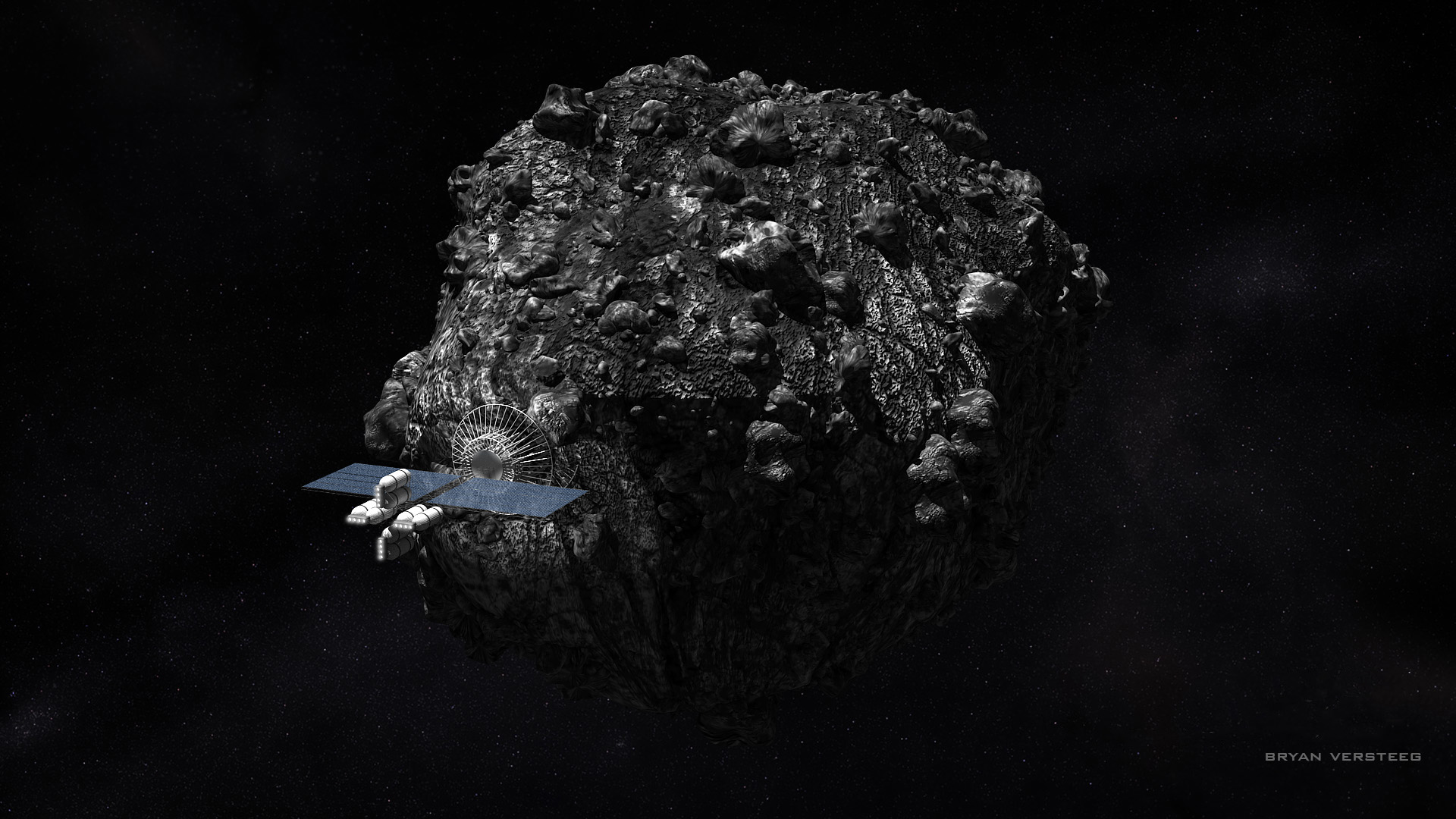

Exploration & resource recovery, Comparison s between Deep Sea Massive Sulphides , Near Earth Asteroids , and terrestrial out cropping mineralization:

Actual and Hypothetical Markets for A steroid materials

(i) for use in-space: water, nickel-iron metal, volatiles, raw silicate; all competing with earth-launch-cost of $5,000 to $10,000 / kg. Need to crack the extraction methodology, but should be straight forward. Will develop as large commercial structures and commercial operations in space take off, trigger will be reqt for (say) 500 tonnes per yr of consumables and / or construction feedstock in orbit.

(ii) for export to Earth: science and collectibles samples (limited market, but high value); PGMs(note that stony irons have ca. 50 ppm PGMs, but again need to crack the extraction-probably using adaptation of Mond process).

| Aspect / Concept | Deep Sea Massive Sulphides | Near Earth Asteroids | Terrestrial outcropping Orebodies ( Open pit mines ) | Deep Orebodies (Underground mining) |

|---|---|---|---|---|

| Target commodities | Base metals, gold | Water, other volatiles, Ni - Fe (for in - orbit market) ; PGMs for return to Earth | Base metals, Gold, etc | Base metals, Gold, etc |

| Discovery comments & methodologies | Remote: Easy discovery by ship - based sonar. Close: ROV for visual inspection & easy sampling (exposed outcropping ore); chem plume detect for active vents | Remote: Earth - based astrometry & spectrometry. Close flyby: visual imaging & IR / laser spectroscopy. Rendezvous: sampling | Remote: Aeromag, gr avity, sat imagery. In - field: Sampling of outcrops | Remote: Aeromag, gravity, sat imagery. Diamond or RC drilling, ? trial mine |

| Target Characteristics | Multiple, small, similar, repeating | Multiple, small, similar bodies (‘single season’ mines) | Large, singular; mine design is always orebody - specific | Poorly defin ed orebody model |

| Success Ratio (% potential deposits likely to be viable) | High - large % of seamounts host VMS chimney strewnfields (?) | High (ca. 30% of NEAs are probable H 2 O and /or Ni - Fe bearing) | Low (99+% of desktop targets fail to make a mine) | Lower... |

| ‘Ore Grade’ ($/tonne) | At 50% Pb - Zn content, washed product is Direct Shipping Ore, value approx $1000/t | At 20% (H 2 O + Ni - Fe), and assuming a market in orbit, value up to $2 x 10 6 /t | At 2% Cu, ore value approx. $150/t | Higher value needed as u/g mining is expensive |

| Recovery Methodology | Remotely operated cutter head | At - asteroid remote regolith | Standard drill & blast, grind | ‘Bog, Bore, Fire’ etc |

| & Economics | with riser to washery on FPSO (Floating Production Storage & Offtake vessel) | collector, later processing at manned orbital facility | & float; emphasis on economies of scale: large low grade open pit ops | |

| Use of technology from other areas | Deep sea oil well technologies (ROVs, FPSOs) | Commsat designs, PV arrays, ion engines, teleoperation technology, planetary mission flyby maths | ---- | Automation and teleoperation making major inroads for access to areas too dangerous for humans. |

| Development Comments | Very low cost trial mining; easy ore access (no pit prestrip, no shaft or decline development); thus reduced project lead time No pit - to - port infrastructure; mobile plant: FPSO built in shipyard; plant moves to sequential mining sites: thus amortize plant cost over several deposits - all lead to re duced CAPEX | Asteroid mining missions are necessarily ‘single - season mines’; miner gets reused on subsequent missions after refurbishment. Split the retrieval and extraction tasks. | High capex , long lead times; enviro and other approvals issues; highly visib le NGO target; landowner identification and compensation issues. Locked in for long operational timelines. | * Very * high cost to access: shaft sink or decline development is high capex, long lead time, and *high risk* |

| Metallurgy | Ultra high grade means low mass throughput, easy beneficiation (simple washing) | Ultra high grade, should make for easy separation of water and Ni - Fe grains | Low grade, always battling to get recovery; significant reagents consumables and labour costs | Same... grade is a bit higher generally, but battling high mining costs |

| Enviro Impact | Low, due to small mass of wash slurry, deposited at 1.5 km depth. No landowner compensation costs | Nil (provided we don’t impact Earth!!) | Requires management of large quantity of chemically contamin ated tailings ; large waste dumps; water balance issues | Reduced enviro impact as much reduced overburden / waste, and much reduced rainfall footprint |

| Transport cost burden | Offload into barge or ore carrier; no pit - to - port infrastructure capex | Pit - to - port infrastructure capex, portside stockpiling | Ditto | |

| Tenure | Either National EEZ, or LOS / International Authority regime | * The true ‘terra nullius’ ! * | State Mining Ordinances: lease with royalty obligations | Ditto |

| Financing | ??? | Sequential and task - specific ?? | Requires all upfront.. | Ditto |